With the rise of electric and hybrid cars, the need for sustainability in the automotive industry has never been greater. Of course, even fully-electric vehicles still need tyres but how environmentally conscious are they?

No matter what car you drive, you eventually need replacement tyres. If you’re environmentally conscious, how you dispose of your old tyres can make a big difference. Keep reading to find out what you can do to help the environment.

What are tyres made of?

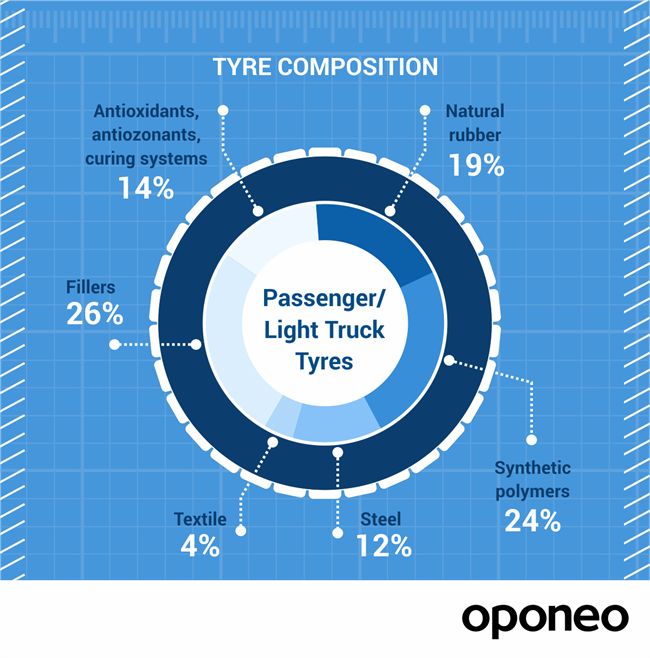

Of course, a tyre is made up of more than just rubber. We have previously covered the complex nature of the construction of a tyre and it’s many parts but, what elements are tyres actually made of?

1. Natural rubber

19% of a tyre is made from natural rubber.

2. Synthetic polymers

The main synthetic rubber polymers used in tyre manufacturing are butadiene rubber and styrene butadiene rubber. They make up 24% of the tyre and are used in combination with natural rubber. Physical and chemical properties of these polymers determine the overall tyre performance such as rolling resistance and wear and traction.

3. Steel

Steel wire is used in the tyre belts and beads. The belts under the tread serve to improve wear performance and the handling of the tyre by stiffening the tyre casing. The bead wire locks the tyre onto the wheel.

4. Textiles

Textiles in tyres are various types of fabric cords that reinforce the tyre. These are mainly fabrics such as: polyester cord, rayon cord, nylon cord, and aramid cord. They provide dimensional stability and help support the vehicle weight.

5. Fillers

Both carbon black and silica are fillers that reinforce the rubber. They improve properties such as tear, tensile strength and abrasion. Using silica also improves rolling resistance.

6. Antioxidants

Antioxidants help to keep the rubber from breaking down due to the effect of temperature and oxygen exposure.

7. Antiozonants

To impede the effects of exposure to ozone on the surface of the tyre antiozonants are used.

8. Curing systems

Sulfur and zinc oxide are crucial ingredients to transform rubber into a solid during tyre curing.

Where does the rubber used in tyres come from?

The tyre industry has one of the largest demands for rubber, but where does the rubber itself come from? Traditionally, it came from Hevea trees.

These trees, originally from Brazil, require a hot, damp environment to thrive, and this is why most natural rubber comes from countries such as India, as they have the right climate to grow the tree.

Today, less than half of the rubber used in tyres is natural. Many sources use synthetic rubber which uses a variety of materials, including crude oil. Natural sap is still used, but the synthetic elements help to provide better parameters, such as heat resistance, which help extend the quality and life of the tyre.

Alternative options

The rubber car tyre has been used throughout motoring history, as few materials come close to matching its ideal properties. It is firm, but offers enough flexibility to give it a variety of functions, as well as making it an easier material to work with.

That being said, modern technology is quickly developing new or alternative rubbers to help improve the situation. The Goodyear tyre group, for instance, is experimenting with Guayule, a desert shrub found along many southern U.S states and Mexico. Since the Hevea tree needs the right conditions, often competing with farming, the Guayule rubber represents a way to easily acquire more natural rubber for tyre production.

The Toyota tyre manufacturer, similarly, is using biosynthetic rubbers for various car parts, which use more natural components. This is mostly used for drive system hoses, but it could soon extend to tyre production as well. Bridgestone, similarly, are designing airless tyres which will use 100% natural materials.

Other companies, of course, are looking to improve the existing tyre rubber and efficiency. Microscopic studs, as seen on the Nokian Hakkapeliitta R2, cuts rolling resistance by as much as 30%. Perhaps more importantly, the microscopic, tiny studs (which are not the same as winter studded tyres) ensure the tyre is still able to perform well, even when worn down.

What happens to old tyres?

Of course, it is possible to repurpose old tyres, by adding new treads. These retreaded tyres have a few benefits and disadvantages which might put some drivers off using them. Despite this, retreading tyres is a great way to use a tyre carcass and the various, undamaged elements of the tyre itself.

Another way to recycle tyres is to simply break them down into their various parts. The steel in the carcass, for instance, can be used in many other production processes, but there are also many uses for recycled tyre rubber. This involves grinding the rubber down into granules, so that is can be used for a wide range of products, including brake pads, road surfaces and even new car tyres.

Likewise, there is always plenty you can do to help recycle your tyres. This involves knowing when to replace them, as well as storing them correctly when not in use, such as when switching between your summer tyres and winter tyres.